One of the most significant challenges in e-mobility is to keep making electric-motor more efficient. At the core of this innovation are permanent magnets, with not only their quality, but also their positioning potentially making a considerable difference in electric-motor performance. Bakker Magnetics in Science Park Eindhoven specialises in smart magnetic engineering, with its own development and production. A hi-tech partner virtually indispensable for the international e-mobility market, with 50 years of experience behind it.

Smart magnetic engineering

making the difference in e-mobility

Hi-tech partner virtually indispensable for the international e-mobility market, with over 50 years of experience

Electric cars, e-bikes, electric busses, trucks and agricultural machinery: our rolling world is rapidly “electrifying”. Global competition in enhancing these vehicles’ electric-motor efficiency, permanent magnets and magnet assemblies are subject to ever-increasing demands. Which makes sense, because high-quality magnets in the perfect setup, with the perfect coating and assembly, mean the highest electric motor output. The question, however, is where can electric-motor developers find a system partner with the right magnet expertise to meet those increased demands? This requires a brief look at the technology; although neither does it end there.

“Our rolling world is rapidly electrifying”

Private Production in China

In terms of e-mobility, Bakker Magnetics focuses mainly on producing rotors and speed sensor rings with permanent magnets for electric drives. The assemblies featuring their own magnets are engineered entirely in-house, according to the customer’s requirements. The company moreover supplies individual magnets for electric motors and generators. ‘These are usually segmented magnets to reduce eddy current effects’, says Maarten de Jonge, Sales Engineer at Bakker Magnetics for e-mobility customers. Developing high-quality magnet solutions for this market means magnet quality must be top notch from the outset. Maarten guarantees this straight away: ‘For many years, we have a production cooperation with the largest manufacturers of neodymium magnets in China. They have a large R&D department, and can handle the highest magnet quality effortlessly. Our partner is constantly developing new magnet grades, with further enhanced properties or with fewer heavy rare-earth elements. This cooperation provides us our very own, absolutely world class, production capacity.

Customised with 0 ppm

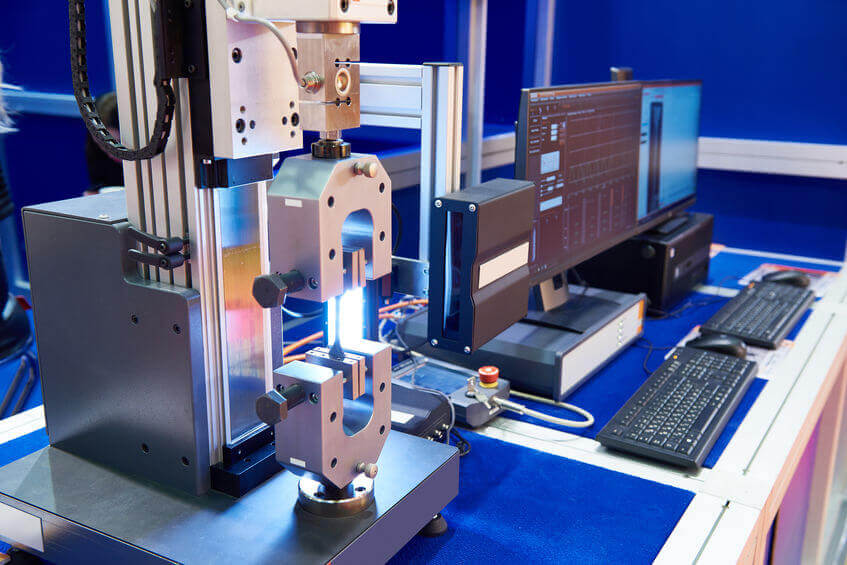

Bakker’s Chinese partner manufactures all grades of neodymium magnets, in every shape, size, volume, temperature resistance and energy density. ‘Even fully customised if that’s what our customer wants’, according to Maarten. ‘This is a major advantage, since it enables us to adapt our magnets and assemblies to the customer’s design, rather than the other way round.’ The Chinese connection can also be regarded as an attractive alternative for simple-assembly series production. Once the magnets from China have arrived at Bakker Magnetics in the Netherlands, each one is inspected in Bakker’s quality laboratory using highly accurate measuring equipment. According to Maarten: ‘We apply a 0 ppm service level. This means that not even one faulty magnet leaves our premises, since everything is tested. For Bakker, the highest quality is always paramount’.

“Our engineers in the Netherlands have vast practical, hands-on knowledge and experience in developing magnet assemblies for various applications, including e-mobility“

Customer Design Optimisation

A major reason behind Bakker Magnetics‘ ability to develop high-quality magnet solutions for the e-mobility market is the high quality of the magnets from China. ‘But there’s more’, says Maarten: ‘Our engineers in the Netherlands have vast practical, hands-on knowledge and experience in developing magnet assemblies for various applications, including e-mobility, meaning we have all the expertise needed for optimising the customer’s basic design inhouse. It starts with selecting magnets. We calculate the most suitable magnet grade based on the design. It could even be a mix that is not for sale as standard, but can be custom-made in China for the customer. We also select the right magnet size for the design, so we can guarantee the most minor tolerances of +/- 0.03 mm. This way, we might eventually select high performance temperature magnets with grades resistant to up to 220 or 240°C, allowing a more powerful electric motor with higher output to be manufactured. We then fit the magnets in the assembly, taking an extremely high angle accuracy of 0.05° into account, which in turn provides additional power. Our methods to ensure that the magnets do not come loose at high rotational speeds include gluing uncoated passivated magnets with an extreme adhesion strength of 15 to 20 Nmm2.’

Enhancing Performance

Maarten explains that there are considerably more technical options for improving electric-drive performance using optimised magnetic rotors or speed sensor rings: ‘For instance, to reduce the eddy current effect we’re able to apply a constant glue layer of 90 microns on small segmented magnets. For e-bikes, we can produce high-precision, multi-pole speed sensor rings with an angle accuracy of 0.4° to improve power assistant operation even further. And when, for instance, we’re asked to engineer and produce the rotor casing, we create that casing with +/- 0.01 mm tolerance, resulting in the smallest air opening and therefore maximum power. With these kinds of assembled products, we oversee the entire supply chain for the customer. We also maintain our warehouse stock levels, if that’s what the customer wants.’

“For e-bikes, we can produce high-precision, multi-pole speed sensor rings with an angle accuracy of 0.4° to improve power assistant operation even further“

True Co-Creation

Applying high-quality, permanent magnets optimally therefore means significantly higher output for electric drives in e-mobility, highlighting the real need for electric-motor developers to find a specialist in this field. ‘You can only call yourself a specialist after gaining the right knowledge and experience, and oversee production,’ according to Maarten. This is why he believes Bakker Magnetics’ future is bright: ‘E-mobility is a fantastic growth market, with permanent magnets taking centre stage. For us, being this market’s benchmark, along with our customers, is what really inspires us. Our Dutch can-do mentality and flexibility mean this is second nature to us. It’s just a question of getting together to think up smart ideas That’s true co-creation. This is smart magnetic engineering. This is Bakker Magnetics.’

Any question? Send me an email.

Want to know more about our magnetic knowledge, please contact me by email form.

I will contact you as soon as possible.

Regards, Maarten de Jonge.