Permanent magnets are found in the electric-motor driving-transport systems of most warehouses and production-environments. However, magnets are also increasingly used for magnet couplings in exacting transport and production-lines components, including those at high temperatures, pressures, in a vacuum or in liquid and chemical processing. The advantage of this is a contactless magnetic coupling, opening up all kinds of intriguing and unexpected possibilities.

Contactless engineering with magnetic couplings in transport- and production lines

Magnetic couplings

Contactless magnetic couplings opening up all kinds of intriguing and unexpected possibilities

Contactless magnetic couplings in conveyor and production lines

For over 50 years, Bakker Magnetics, based in Science Park Eindhoven, has specialized in the engineering and production of magnet assemblies for electric drives. These systems are found in warehouses and production lines worldwide. Less well-known, however, is Bakker’s growing involvement in magnetic couplings used in these same automated environments.

According to the engineer, this is starting to change: “Contactless technology allows force transmission under critical conditions without requiring a wall opening. This eliminates the risk of leakage or pressure loss. And when the right magnets are selected, the couplings can also operate maintenance-free under extremely high temperatures.”

“Contactless technology means forces can be transferred under critical conditions, without wall opening being required“

Engineering excellence behind every coupling

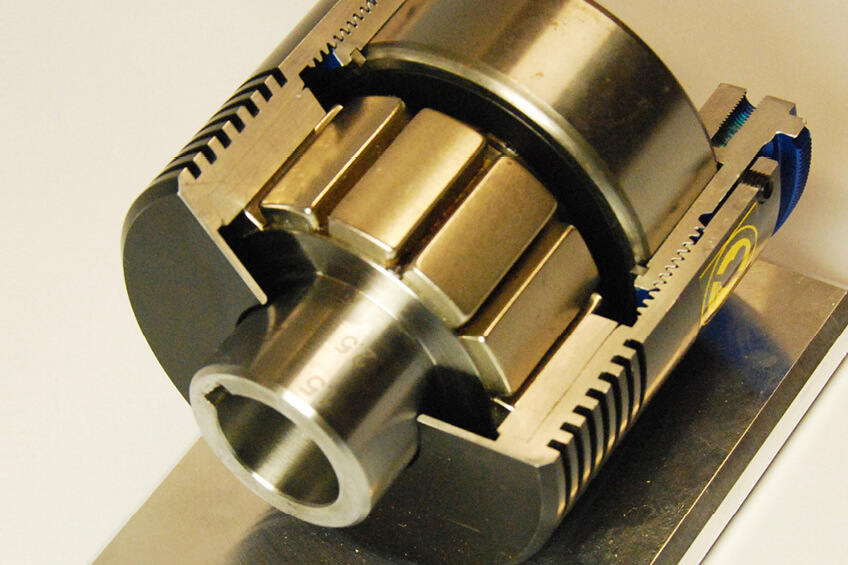

A magnetic coupling typically consists of two magnet arrays, usually multi-magnet configurations, facing each other across an air gap. When one side rotates, the other follows, without any physical contact. The magnetic fields can even operate through a solid wall. While magnetic couplings have existed for some time, their industrial use has only gained traction recently.

“In the past, many transport and production system designers simply didn’t consider magnetic couplings,” says the specialist. “Now they’re discovering the range of possibilities. Advancements in magnet materials and mounting techniques have enabled us to meet increasingly demanding requirements, opening new areas of application.”

Bakker Magnetics engineers and manufactures magnetic couplings in the Netherlands. Magnets and select assemblies are produced in China through a joint venture with one of the country’s largest and most advanced magnet factories. “We maintain full responsibility,” explains the engineer. “Every magnet shipped to the Netherlands is inspected in our quality lab with precision measurement tools. Whether Permanent Magnets, Hard Ferrite magnets, Neodymium magnets, Samarium Cobalt magnets or ALNiCO magnets, not a single subpar magnet is passed on to our customers. Quality is always our top priority.”

Inspirational Examples

To illustrate the potential of magnetic couplings, the specialist shares several real-world examples. “Take a product that needs processing in a high-temperature oven under pressure. The product is moved on special rollers driven by magnetic couplings positioned outside the oven. This avoids heat or pressure loss and enables a maintenance-free solution.”

“In such cases, we might use high-grade neodymium magnets or samarium cobalt (SmCo) magnets, which retain their properties at temperatures up to 300°C,” the engineer adds. Another scenario is a mixer that blends caustic or hazardous liquids. “The rotor is powered via a contactless magnetic coupling through a sealed wall, making the setup leak-free and low maintenance, even in environments up to 65 bar.”

A special design, the hysteresis coupling, replaces one magnet assembly with a non-ferromagnetic material like aluminum or copper. “This lets the coupling slip slightly, allowing torque to be adjusted, ideal for applications like bottle-cap screwing systems.”

“Another feature of hysteresis magnetic couplings is their use in slowing down motion“

Unexpected but impactful uses

Hysteresis magnetic couplings also function as braking systems. “They’re used in rollercoasters, where a linear magnetic brake interacts with an aluminum plate, guaranteeing reliable braking even during power outages,” says the specialist. “This principle can also slow items moving too fast on a conveyor belt.”

Magnetic couplings can even be integrated into product components. “Take a large industrial ventilator,” the engineer explains. “Misalignment in shafts and bearings causes vibration, noise, and wear. A central magnetic coupling eliminates this issue, even at high rotational speeds of up to 3,500 rpm. It also reduces the maintenance burden, no more constant bearing replacements.”

A scalable and sustainable technology

The specialist sees growing interest in magnetic couplings: “It’s a cutting-edge, future-proof technology—safe, clean, reliable, and efficient. But it still flies under the radar. Engineers, installers, and developers need to know it exists. That’s when they’ll come knocking.”

Bakker Magnetics doesn’t offer a standard product range; instead, the company focuses on custom solutions. “We design the magnetic coupling around the customer’s needs, not the other way around,” the engineer emphasizes. “Dimensions, forces, torque levels, extreme environments, you name it, we can handle it. We’ve developed couplings with diameters of a meter and torque ratings up to 550 Nm.”

From concept to realization: true co-creation

“This technology is our specialism. We do the calculations, perform simulations, and provide complete system knowledge, from concept to delivery,” the specialist concludes. “It’s co-creation in the purest form. That’s what smart magnetic engineering means at Bakker Magnetics.”

Any question? Send me an email.

Want to know more about our magnetic knowledge, please contact me by email form. We will contact you as soon as possible.

Regards, team MTA

"*" indicates required fields