At Bakker Magnetics, we have been developing and producing high-quality magnetic solutions for industrial applications for decades. One of the core technologies gaining increasing attention is the magnetic coupling.

This innovative technique is often compared to the traditional mechanical coupling. But what are the differences, and why are more and more companies choosing a magnetic solution?

What are magnetic couplings and how do they work?

A magnetic coupling is a contactless connection between two shafts, driven by magnetic fields instead of mechanical contact. This allows torque to be transmitted without wear, leakage, or friction. This makes the technology particularly interesting for sectors where reliability, low maintenance, and energy efficiency are crucial.

What are mechanical couplings and their limitations?

Mechanical couplings, often based on direct physical or hydraulic contact, transmit speed or torque through a fixed connection. While these systems are robust and widely used, they come with disadvantages:

- Wear due to friction

- Higher maintenance costs

- Risk of leakage (in hydraulic systems)

- Limited efficiency under extreme loads

Why choose magnetic couplings instead of mechanical couplings?

- Maintenance-free: with no direct contact, components hardly wear out.

- Energy-efficient: lower losses and better power transmission.

- Safe: in case of overload, the system automatically disengages to prevent damage.

- Durable: reduced wear and energy consumption contribute to longer service life and lower TCO (Total Cost of Ownership).

- Leak-free: ideal for pumps and systems where fluid tightness is essential.

Applications of magnetic couplings in various industries

At Bakker Magnetics, we supply magnetic couplings for a wide range of industries, including:

- Pumps in the chemical and pharmaceutical sector

- Compressors and fans in HVAC and energy

- Food industry, where hygiene and reliability are top priorities

- High-tech machines where precision and low-maintenance operation are required

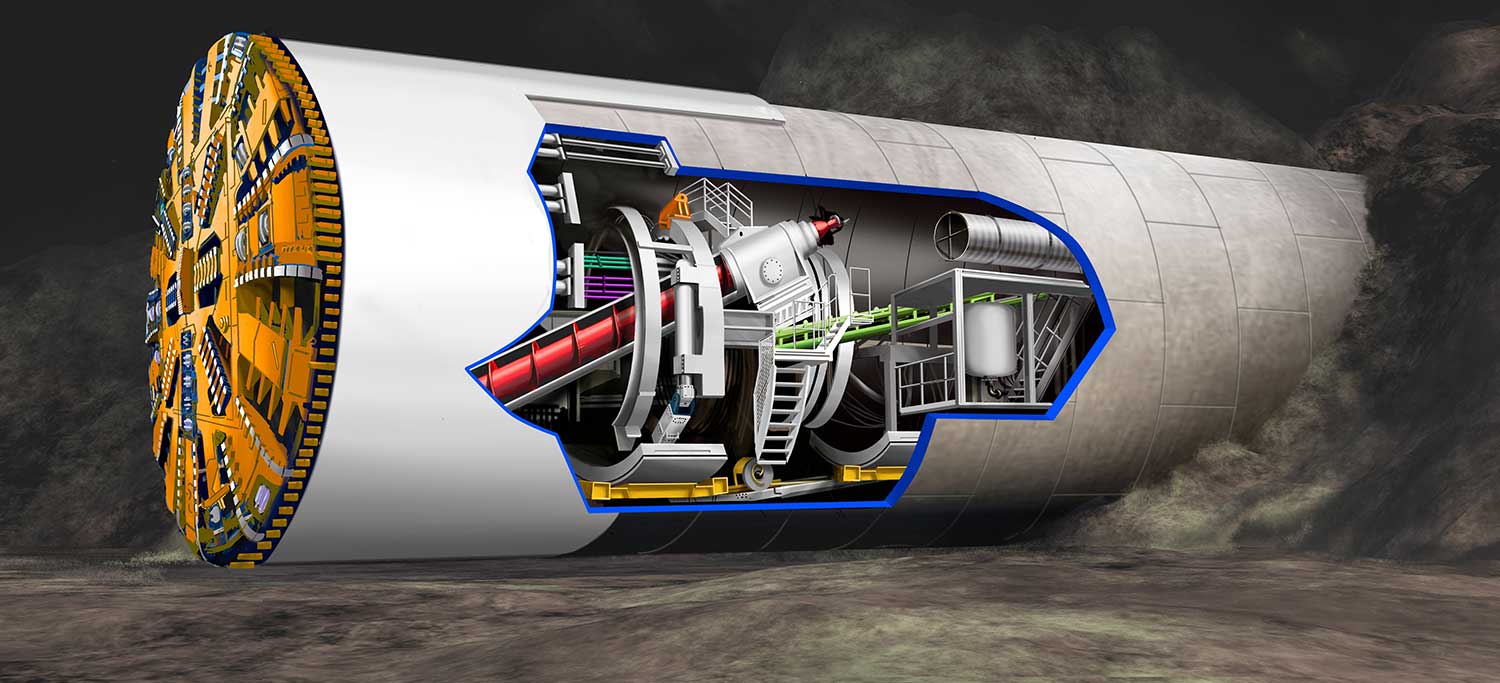

- Mining industry, where robustness and reliability under harsh conditions are essential

- Offshore applications, focusing on safety and leak-tightness in extreme environments

Engineering & Design. Collaboration or full customization

A key advantage of Bakker Magnetics is our flexible approach to working with customers. Our experienced engineers can assess and optimize your supplied magnetic coupling design to ensure the best performance. In addition, we can design and manufacture completely new magnetic couplings tailored to your specific application. This ensures you receive a solution that delivers the best technical and economic results.

The strength of Bakker Magnetics in innovative magnetic couplings

Where mechanical couplings were the standard for many years, magnetic couplings today provide a smarter, safer, and more sustainable alternative. At Bakker Magnetics, we combine our in-depth knowledge of magnetism with innovative engineering to develop solutions that perfectly match our customers’ needs. Whether it’s optimizing an existing design or fully designing and producing a new magnetic coupling, we ensure maximum efficiency, reliability, and lifetime.

Let’s see together how Bakker Magnetics’ innovative magnetic couplings can take your drive technology to the next level and contact our engineering team for a tailor-made solution.