In industrial applications, Permanent Magnets are not commodity components. Their behavior is governed by physics, materials science, and system integration. Yet in practice, magnets are still often selected solely based on dimensions and nominal pull force. This frequently leads to performance loss, premature failure, or unnecessarily high costs.

At Bakker Magnetics, we analyze magnetic applications on a daily basis in sectors such as automation, machine building, energy, and mobility. Based on this experience, we consistently observe five structural mistakes in the selection and integration of Permanent Magnets.

Assessing magnetic force without system analysis

A common misconception is that the pull force stated on a datasheet equals the actual force in the application. In reality, this value is measured under ideal conditions: a perfectly flat, thick steel surface with no air gap.

In practice, the following factors play a role:

- Air gaps caused by tolerances, coatings, or adhesive layers

- An incomplete magnetic circuit

- Dynamic loads (vibrations, accelerations)

- Shear forces instead of pure tensile forces

Even an air gap of only a few tenths of a millimeter can reduce the effective force by tens of percent.

Technical recommendation

- Analyze the magnetic circuit as a whole

- Calculate safety factors for dynamic loads

- Use FEM simulations or practical testing to validate the actual force

Insufficient consideration of temperature and demagnetization

Each magnetic material has its own temperature coefficient and maximum operating temperature. If this limit is exceeded, (partial) demagnetization occurs—often irreversible.

Examples:

- NdFeB (neodymium): high energy density, but temperature-sensitive

- SmCo (samarium-cobalt): lower maximum force, but excellent thermal stability up to >300 °C

- Ferrite: low cost and stable, but limited magnetic performance

In addition, there is a risk of demagnetization caused by external magnetic fields or opposing magnetic forces in motors and actuators.

Technical recommendation

- Select not only on maximum force, but also on coercivity (Hc, Hcj)

- Consider peak temperatures, not just nominal values

- Analyze counter-fields in electromagnetic systems

Incorrect material choice in corrosive or humid environments

Neodymium magnets are highly susceptible to corrosion. Without protection, moisture can penetrate, leading to oxidation, volume expansion, and ultimately mechanical damage.

Commonly used coatings include:

- Nickel–copper–nickel (NiCuNi)

- Epoxy

- Parylene

- Mechanical encapsulation in stainless steel, plastic, or steel

The correct choice depends on chemical exposure, wear, cleanliness requirements, and expected service life.

Technical recommendation

- Analyze the chemical environment (salts, oils, cleaning agents)

- Consider encapsulation for critical applications

- Test coatings under accelerated aging conditions

Underestimating shape, magnetization direction, and mounting

Magnetic performance is strongly influenced by:

- Geometry (ring, disc, segment, block)

- Magnetization direction (axial, diametrical, multipole)

- Interaction with ferromagnetic components

A poorly chosen shape or magnetization direction can lead to flux leakage, uneven forces, or unwanted magnetic interactions with surrounding components.

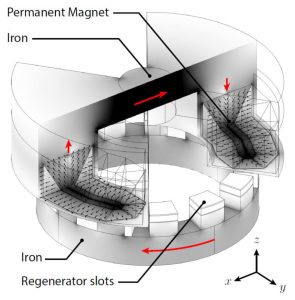

Technical recommendation

- Design magnets as part of the total mechanical assembly

- Optimize flux guidance using pole pieces or soft magnetic materials

- Avoid standard solutions where custom assemblies deliver better performance

Underestimating mechanical fragility and service life

High-performance Permanent Magnets are often brittle and sensitive to shock loads. Neodymium and samarium-cobalt magnets have high hardness but low toughness. Without proper mechanical fixation, cracking or chipping may occur, leading to functional failure or safety risks.

Technical recommendation

- Always design magnets to be stress-free

- Avoid direct impact loads

- Integrate magnets into assemblies with structural support

From component to engineering solution

The common thread in all these mistakes is that magnets are too often treated as standalone components. In reality, they function as part of a physical system in which mechanics, thermal behavior, and magnetism interact.

At Bakker Magnetics, we support our customers with:

- Development of customer-specific magnetic assemblies with PM

- Material and system-level advice

- Magnetic simulations

- Prototype development and validation testing

By involving magnets early in the design process, our customers achieve higher reliability, lower total cost of ownership, and predictable performance throughout the entire service life of their systems.